Reference:

Site pumps

Max flow : 324 m³/h

Max. height : 62m

Get a quote

During the production process, food products have to be transferred several times from one station to another. From a hygienic point of view, it is advantageous to carry out this transport inside closed systems. For this reason, it is often food pumps that are responsible for transferring fluid or pasty products as well as non-fluid products. An alternative method would be to use conveyor belts and containers, but continuity of transport could not be guaranteed.

Submersible electric pumps suitable for the drainage of clear and turbid water. They can be used as ready-to-use portable pumps either on sites and sumps, or for fixed installations with a control box.

Operation: Site pump Max temperature pumped liquid: 40°C Max temperature operating temperature: 40°C Max time operating time with Q=0: 10s Ph of the pumped liquid: 5÷8 Density of the treated liquid: 1kg/dm3 start/hour max. : 8 p.m. Free passage: 6mm Fluid: Clear water Max immersion depth: 20m

Lid: Anticorodal aluminum alloy Motor casing: Aluminum alloy EN-AW 6060 Pump body: Anticorodal aluminum alloy Strainer: Anticorodal aluminum alloy Wear plate: HYDRO 10M-10T-15T AISI 304 stainless steel HYDRO 15M-20M-20T-30T anticorodal aluminum alloy with anti-wear rubber coating Impeller: Cast iron in EN GJL 200 (UNI EN 1561) Mechanical seal: Silicon carbide/Silicon carbide (SiC/SiC) Motor shaft: AISI 420 stainless steel Fasteners: Class A2 stainless steel Electric cable: 10 meters type H07RN-F

Power supply: 220/240V~1 – 380/400V~3 Frequency: 50Hz Power: 1.0 ÷ 2.2kW Poles: 2 Vertical discharge: G1 1/2″ ÷ G2″ Wheel Type: Open Wheel ambient temperature max. : 40°C Max flow : 54m3/h Max lifting height : 20m

Submersible electric pumps suitable for the drainage of clean and turbid water. They are also suitable for use in construction sites and for the pumping of abrasive liquids.

Operation: Site pump Max temperature pumped liquid: 40°C Max temperature operating temperature: 40°C Max time operating time with Q=0: 10s Ph of the pumped liquid: 5÷8 Density of the treated liquid: 1.1kg/dm3 start/hour max. : 8 p.m. Free passage: 6mm Fluid: Clean water Max immersion depth: 20m

Pump body: Cast iron in EN GJL 200 (UNI EN 1561) with anti-wear rubber coating Wear plate: Cast iron in EN GJL 200 (UNI EN 1561) with anti-wear rubber coating Motor casing: Cast iron in EN GJL 250 (UNI EN 1561) Cover: Cast iron in EN GJL 250 (UNI EN 1561) Wheel: High chrome cast iron Motor side mechanical seal: Ceramic/Graphite Pump side mechanical seal: Silicon carbide/Silicon carbide (SiC/SiC) Motor shaft: AISI 431 stainless steel Strainer: AISI 304 stainless steel Cooling box: AISI 304 stainless steel Fasteners: Class A2 stainless steel Electrical cable: 20 meters 7G4+2×1.5mm² type 07RN-F for Y/Δ starting

Power supply: 220/240V~1 – 380/400V~3 Frequency: 50Hz Power: 11 ÷ 15kW Poles: 2 Vertical discharge: G4″ ÷ G6″ Wheel Type: Open Wheel ambient temperature max. : 40°C Max flow : 252m3/h Max lifting height : 62m

Submersible electric pumps suitable for the drainage of clear and turbid water. They can be used as ready-to-use portable pumps either on sites and sumps, or for fixed installations with a control box.

Operation: Site pump Max temperature pumped liquid: 40°C Max temperature operating temperature: 40°C Max time operating time with Q=0: 10s Ph of the pumped liquid: 6÷10 Density of the treated liquid: 1.0 kg/dm3 start/hour max. : 8 p.m. Free passage: 6mm Fluid: Clear water Max immersion depth: 5m

Cover: Cast iron in EN GJL 200 (UNI EN 1561) Pump body: Cast iron in EN GJL 200 (UNI EN 1561) Strainer: AISI 304 stainless steel Impeller: Cast iron in EN GJL 200 (UNI EN 1561) Engine side trim: Sealing Ring Pump side mechanical seal: Silicon carbide/Silicon carbide (SiC/SiC) Motor casing: AISI 304 stainless steel Motor shaft: AISI 420 stainless steel Fasteners: Class A2 stainless steel Electric cable: 10 meters type H07RN-F

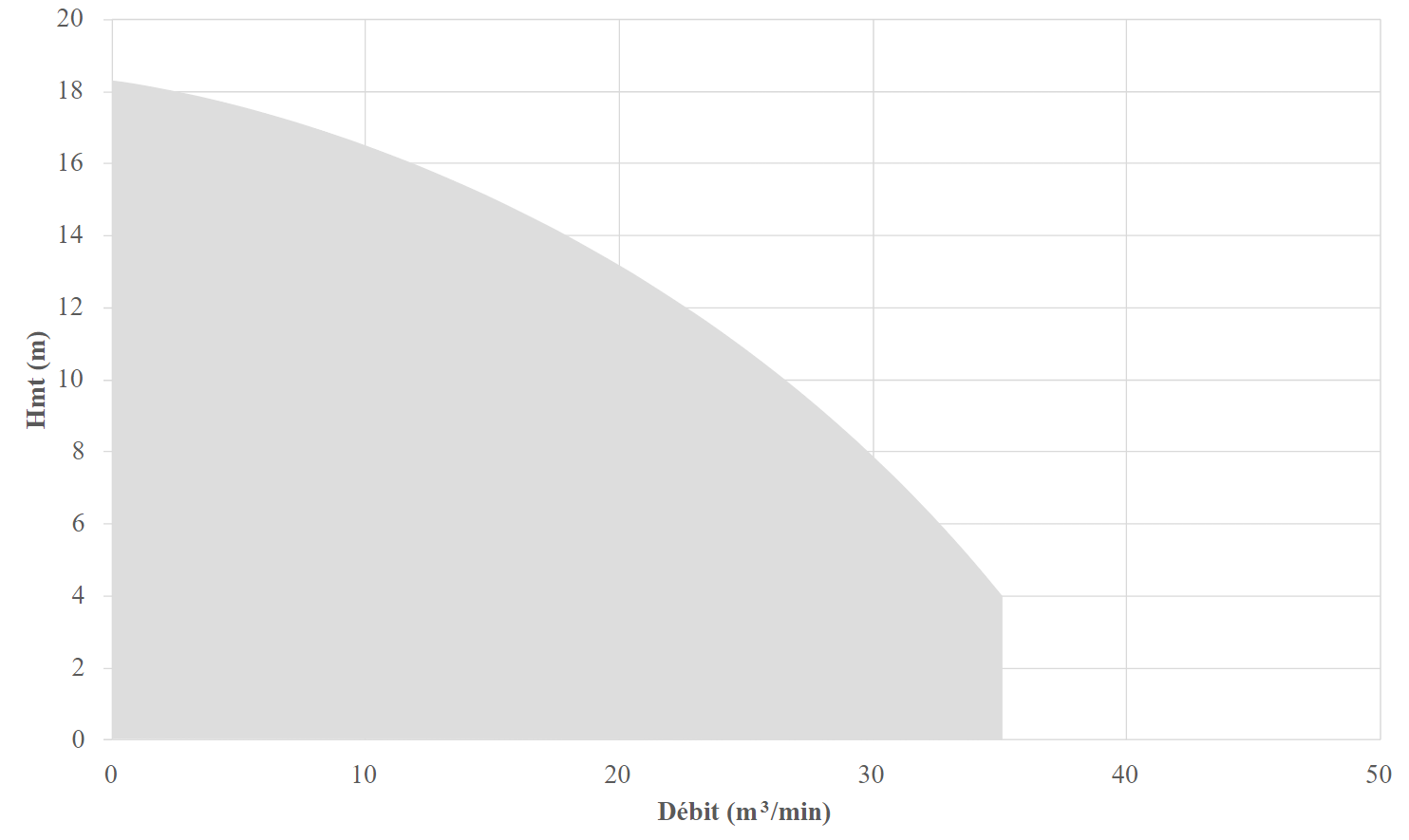

Power supply: 220/240V~1 – 380/400V~3 Frequency: 50Hz Power: 0.9 ÷ 1.40kW Poles: 2 Vertical discharge: G2 ISO 228 Wheel Type: Open Wheel ambient temperature max. : 40°C Max flow : 36m3/h Max lifting height : 18m

Submersible electric pumps suitable for the drainage of clean and turbid water. They are also suitable for use in construction sites and for the pumping of abrasive liquids.

Operation: Site pump Max temperature pumped liquid: 40°C Max temperature operating temperature: 40°C Max time operating time with Q=0: 10s Ph of the pumped liquid: 5÷8 Density of the treated liquid: 1.1 kg/dm3 start/hour max. : 10am Free passage: 7mm Fluid: Clean water Max immersion depth: 20m

Lid: Anticorodal aluminum alloy Motor casing: Anticorodal aluminum alloy Pump body: Anticorodal aluminum alloy with anti-wear rubber coating Strainer: Anticorodal aluminum alloy Wear plate: Stainless steel with anti-wear rubber coating Wheel: Stainless steel Motor side mechanical seal: Ceramic/Graphite Pump side mechanical seal: Silicon carbide/Silicon carbide (SiC/SiC) Motor shaft: AISI 431 stainless steel Fasteners: Class A2 stainless steel Electric cable: 20 meters type H07RN-F 4G4mm² double cable for Y/Δ starting

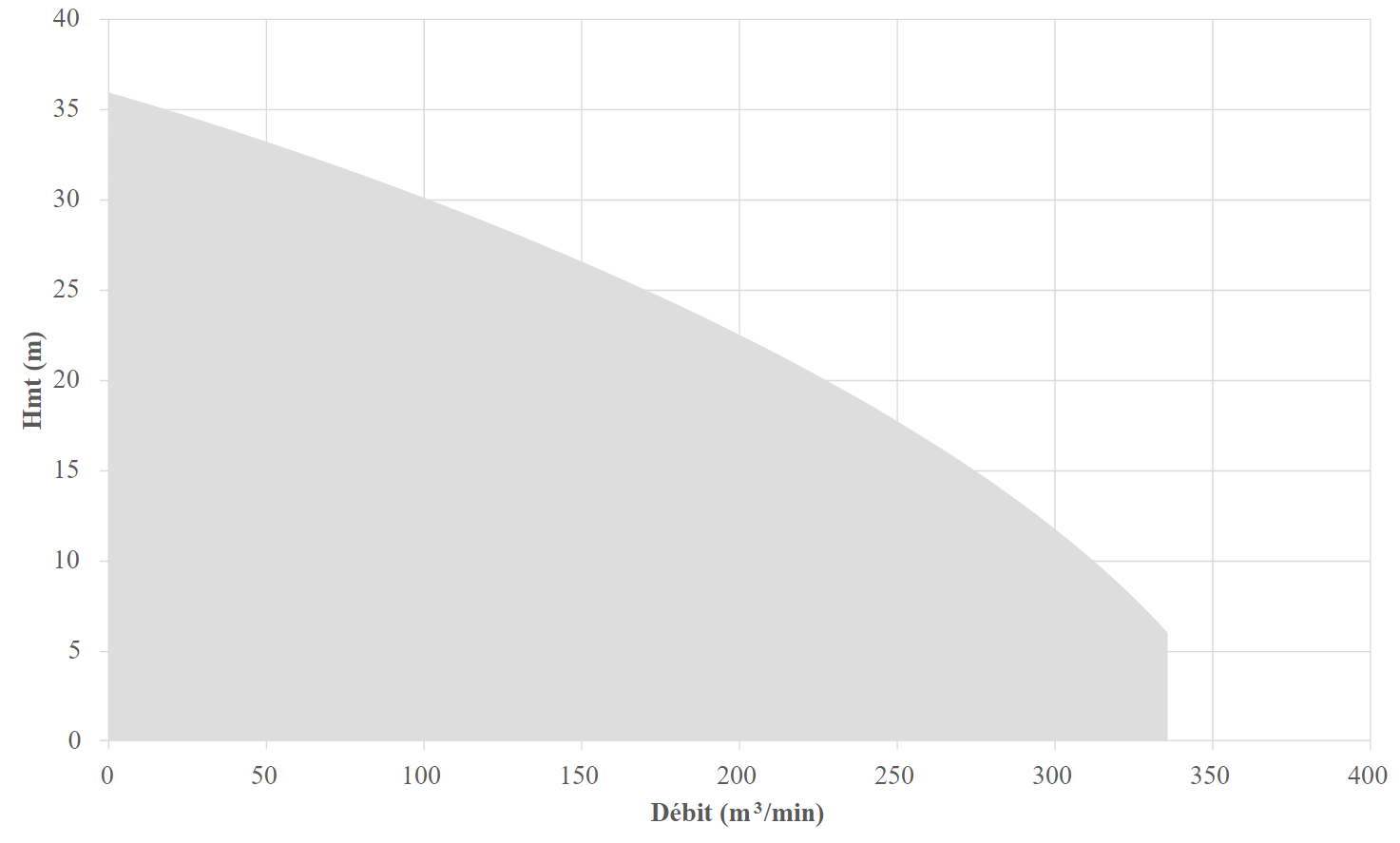

Power supply: 380/400 V ~3 Frequency: 50Hz Power: 22kW Poles: 2 Vertical discharge: G6 Wheel Type: Open Wheel ambient temperature max. : 40°C Max flow : 324m3/h Max lifting height : 35m

Submersible electric pumps suitable for the drainage of clear and turbid water. They are suitable for use in construction sites for the pumping of abrasive liquids. For their maneuverability they can be easily transported.

Operation: Site pump Max temperature pumped liquid: 40°C Max temperature operating temperature: 40°C Max time operating time with Q=0: 10s Ph of the pumped liquid: 5÷8 Density of the treated liquid: 1.1 kg/dm3 start/hour max. : 8 p.m. Free passage: 6mm Fluid: Clear water Max immersion depth: 20m

Lid: Anticorodal aluminum alloy Motor casing: Anticorodal aluminum alloy Pump body: Anticorodal aluminum alloy Strainer: AISI 304 stainless steel Wear plate: Anticorodal aluminum alloy with anti-wear rubber coating Impeller: MARTENSITIC STAINLESS STEEL Motor side mechanical seal: Ceramic/Graphite Pump side mechanical seal: Silicon carbide/Silicon carbide (SiC/SiC) Motor shaft: AISI 420 stainless steel Fasteners: Class A2 stainless steel Electric cable: 10 meters type H07RN-F

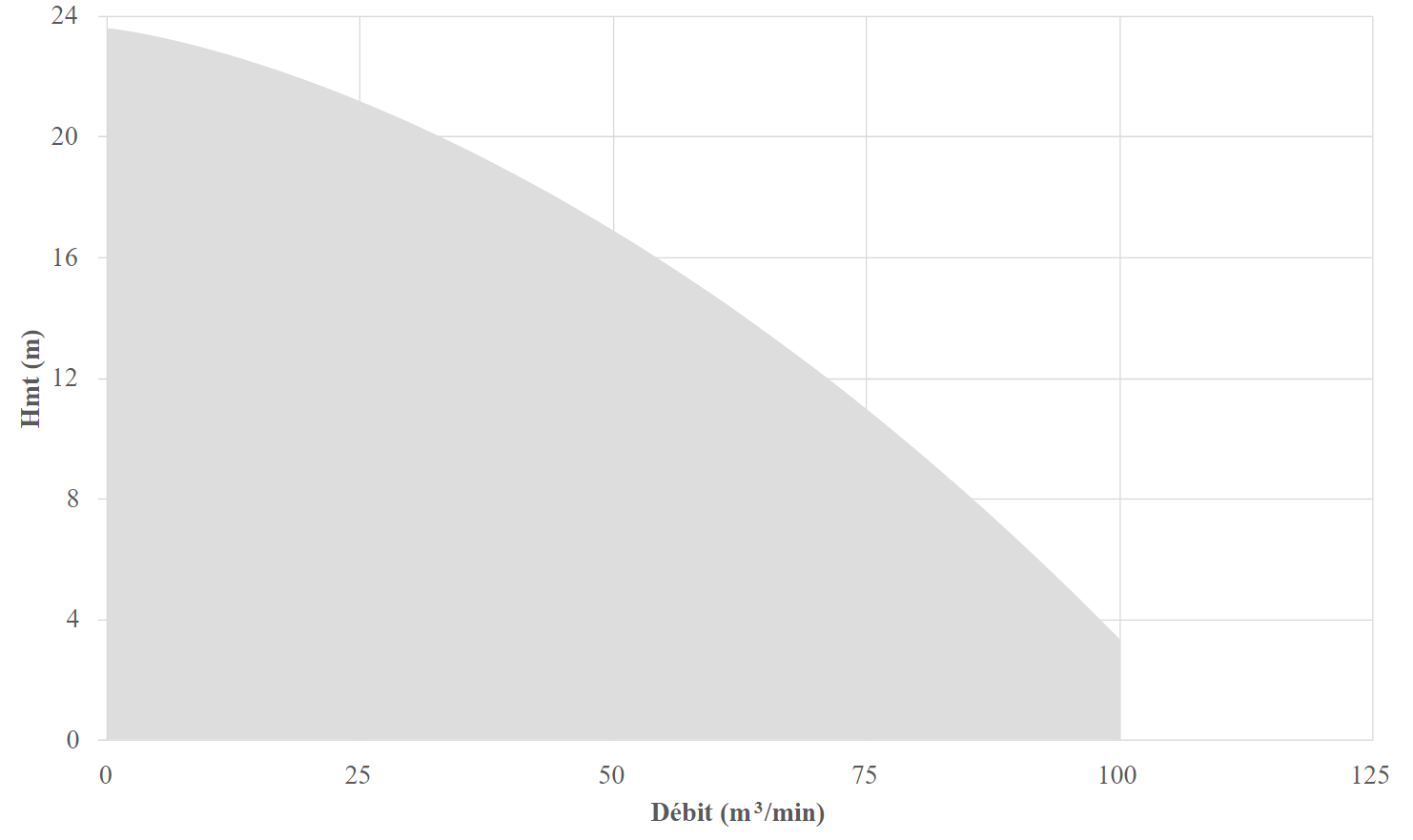

Power supply: 380/400 V ~3 Frequency: 50Hz Power: 2.2 ÷ 4.1kW Poles: 2 Vertical discharge: G2 1/2″ ÷ G3″ Wheel Type: Open Wheel ambient temperature max. : 40°C Max flow : 100.8m3/h Max lifting height : 23.3m

Ranges

Description

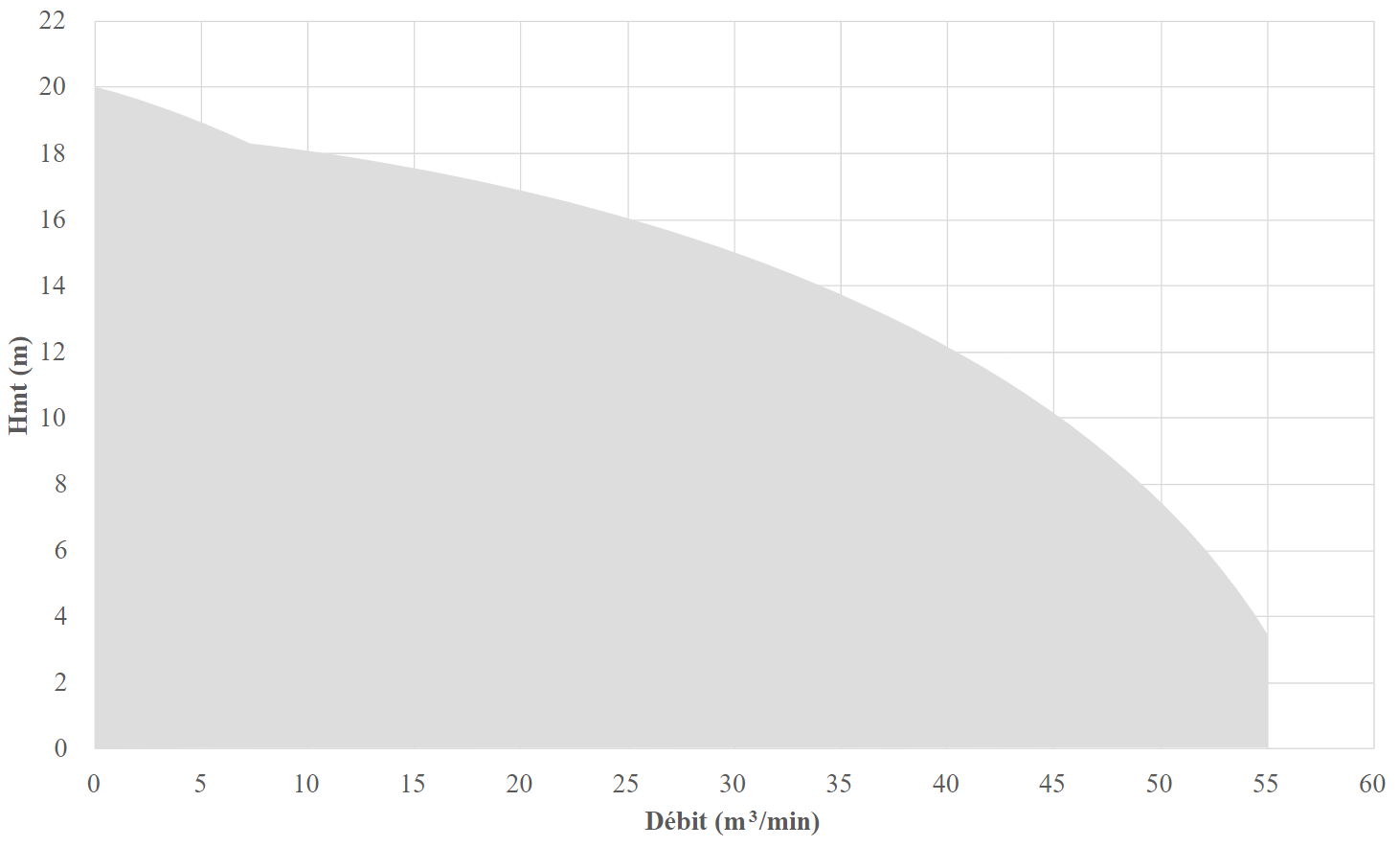

Operating ranges

Materials

Range Features

Description

Operating ranges

Operating characteristics

Materials

Range Features

Description

Operating ranges

Operating characteristics

Materials

Range Features

Description

Operating ranges

Operating characteristics

Materials

Range Features

Description

Operating ranges

Operating characteristics

Materials

Range Features